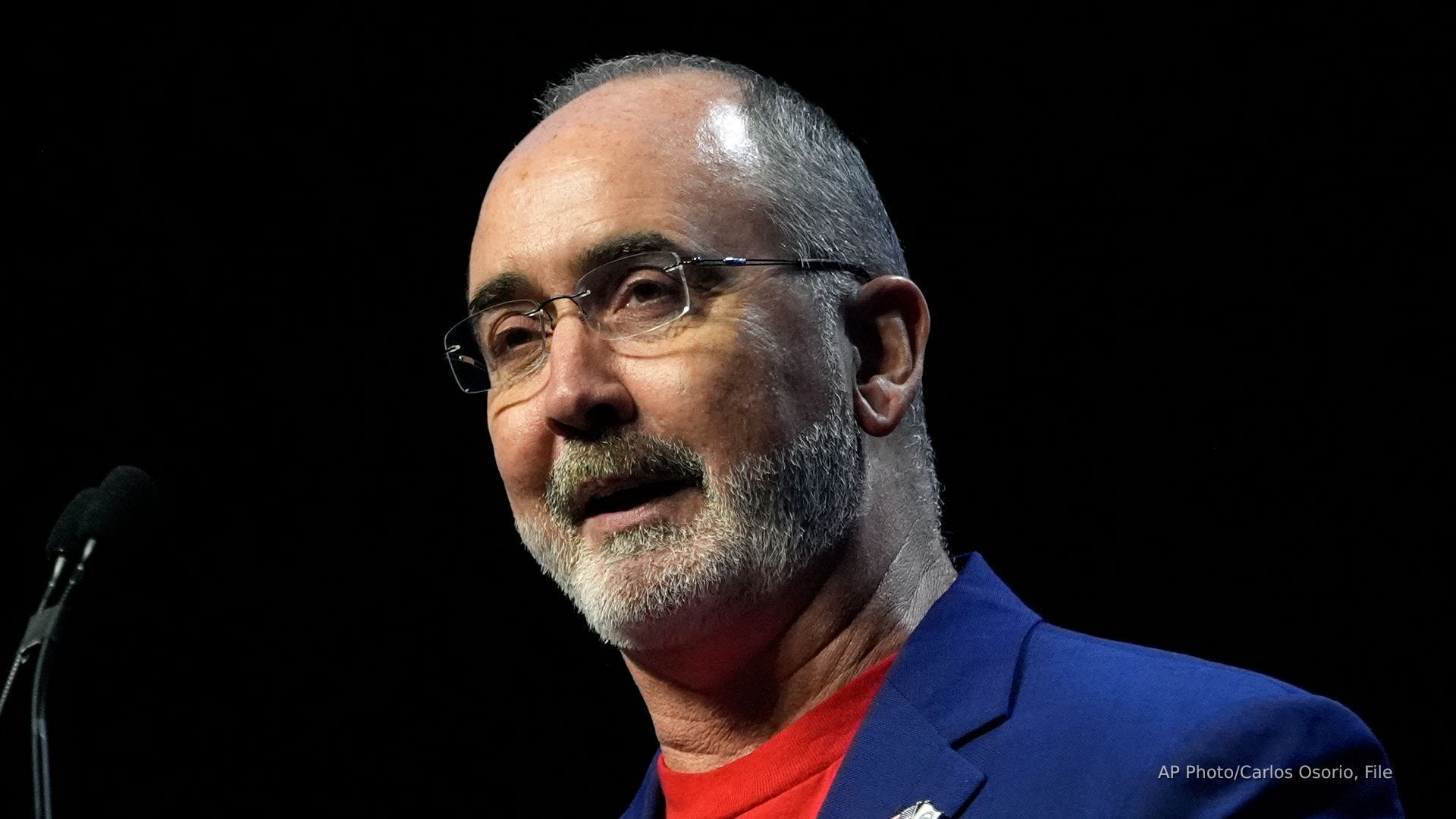

UAW President Sean Fein supports Trump’s car rates

The chairman of the United Autoworker Union praises President Trump’s tariffs on foreign-made vehicles, but says it cannot stop there.

Straight Arrow News

- The UAW says the lack of utilization of automotive factories is not a coincidence, and it is calling on carmakers to build more vehicles in the US.

- Automation is one reason for the number of automotive manufacturing jobs today, one expert notes.

The UAW hopes that more vehicles will be built in the US, and the union says it is very likely that the country’s underutilized automotive factories will increase employment.

Not to mention that once it reaches full existing capacity, it will include “a greater 630,000 people in other parts of the US economy,” according to the union.

The union’s claims coincided with UAW President Sean Fein’s President Donald Trump’s car rate embrace, but tariffs were not cited in the union’s white paper “Unlocking the possibilities of US automobile manufacturing capabilities” published in April. This report, which has gained mixed reactions from watchers in several industry, does not appear to refer to the production of automotive parts, a key part of the automotive sector.

The paper argues that 16 Ford Motors, including GM Roadstown in Ohio, General Motors, Stellantis and Volkswagen plants can afford it, and that the automaker has an infrastructure to produce millions of vehicles.

“In 2024, the US automotive industry had the capacity to build more than 14.7 million vehicles. However, only 10.2 million vehicles were produced, leaving 4.5 million unused capacity, according to the white paper.”

The report calls this inadequate not by chance, but rather the result of a deliberate strategy of entering offshoring, stock buybacks and short-term profits rather than investments in union work, strong communities, and long-term stability.

This message is simple and urges the industry to “step up” as it did during the COVID-19 pandemic between the “weapons of democracy” and the production of medical devices in World War II. The UAW planned rallies in Trenton and Warren on May 5 and 6, respectively, calling on Stellantis, owner of Jeep, Lamb, Chrysler, Dodge and Fiat, to “have full advantage of the excess capacity of American plants.”

“We don’t need to break through the ground with a single new plant to rapidly grow the production capacity of our cars, not the skills of the plants we built, the communities we rely on these jobs,” Fain said in a news release.

The Free Press has asked several automotive industry watchers to consider the union’s white paper.

Harley Scheiken, labor expert and professor emeritus at the University of California, Berkeley:

“The UAW paper states the important point: “The American automotive industry has a proud heritage of facing national challenges.” …

“We add that the Detroit Treaty signed by Walter Leuser and GM after World War II lays the foundation for creating a vast expansion of the middle class, the most important model created from Detroit.

“That being said, this paper is incomplete in its current form. It doesn’t mention the type of vehicle produced in ice (gas-powered) or EV (electric vehicle). Last year, about half of China’s production was EV or hybrid. At key moments, it further damaged the environment, while lagging behind both competitively.

“As a result of not mentioning EVS, this paper talks about unused production “space.” Billions of new tools are needed, and it takes two to five years.

“Unprecedented chaos in the administration’s tariff policy gives ‘chaos’ a bad name. Anything introduced at 9am on a certain day could be thrown away at noon or significantly revised.

Malick Masters, Wayne State University Workers Expert and Professor Emeritus:

“I have read this paper and it presents data to reinforce UAW’s claim that the US automotive manufacturing sector (I read as automotive assembly) can be adopted to offset vehicle tariffs.

“Data on unused capabilities from government sources shows the potential for growth in capacity utilization. They use simple calculations from the Federal Reserve data on expected employment benefits if this was done by Big Three, and Plus.

“But that doesn’t mean there is a demand for the products that existing facilities are installed to assemble. (North America) production footprint and supply chain are intricately linked connection parts and assembly for vehicles of a particular brand. What’s more, companies are in a state of transition to EVs.

“There’s a lot to be needed to deny the US, perhaps a valuable purpose. A few key things come to mind right away. Perhaps most importantly, reducing the regulatory burden of manufacturing, reducing energy capacity in this sector, reducing corporate tax rates, reducing general tax rates, depreciation and capital investments.

“I think a large part of Trump’s policy on automotive rates is directly aimed at China, one of the world’s leading automotive manufacturers and EV producers. It doesn’t have the same regulatory burden as subsidizing car production and operating in the US, and it has significantly lower labor costs than the US.”

Sam Fiorani, Vice President of Global Vehicle Forecast at Autoforecast Solutions

“Comparing plants’ ability to make ice and their ability to make upgraded plants EVS is not a comparison between apple and apple. Many of these plants, such as Orion, Factory Zero and Spring Hill, are trying to ramp up for the future of electricity. To make AVS most efficient, assembly lines cannot easily switch between traditional cars and trucks and modern EVs.

“Just because of competence does not mean that (IT) can be met. U.S. buyers cannot choose the entry-level model currently imported, unless UAW workers are willing to cut pay or increase automation in these factories.

“Many of the current levels of employment in the industry are due to increased automation, which is something UAW doesn’t want to acknowledge. It requires fewer people to build vehicles today. An increase in automation could open up plants to the low-cost production model that the market needs, but that would counter the drives of UAW members.

“Ignoring the benefits of the USMCA reduces the nature of US competition by closing doors for exports and increasing prices for vehicles and components for American buyers.”

Eric D. Lawrence: Please contact elawrence@freepress.com. Become a subscriber. Send a letter to the editor at freep.com/letters.